Axis modules 1-channel AX8118 - Beckhoff Viet Nam

AX8118 | Single-axis module 18 A

AX8118 | Axis modules 1-channel

An axis module contains the DC-Link and the inverter for supplying the motor. Depending on the required number of axes, the axis modules are attached to the supply module to form the multi-axis servo system. Axis modules with different ratings can be combined in order to enable an optimised design of the individual axes.

Supporting a wide supply voltage range from 100 to 480 V AC, the axis modules can be operated without limitation with any of the supply modules. This flexibility simplifies the implementation of machine configurations for any type of mains supply. The electrical connection is established without tools via the already integrated AX-Bridge: it automatically connects DC-Link, 24 V DC control voltage and communication via EtherCAT between the linked modules. The DC-Link connection enables the exchange of energy during acceleration and braking procedures, where the regenerative brake energy is primarily stored in the common DC-Link. If the energy exceeds the DC-Link capacitance, utilize the brake resistor of the AX881x capacitor modul to suppress the DC-Link voltage. The AX8000 multi-axis servo drive system encompasses new functions of safe drive technology with TwinSAFE: the AX8108, AX8118 and AX8206 axis modules include a programmable TwinSAFE Logic corresponding to an EL6910 and enable the direct implementation of a safety application in the servo drive. The user enjoys greater degrees of freedom in the implementation of safety applications in drive technology systems, and the flexibility in programming facilitates individual design of safe drive technology to suit the specific system. The safety functions STO and SS1 can be implemented with the TwinSAFE axis modules with the ordering option -0100 (STO/SS1). These functions can be initiated both via hard wiring and via FSoE. For TwinSAFE axis modules with the ordering option -0200 (Safe Motion), various internal and external drive signals are available for implementing an application-specific safety function. As usual, these can be interconnected with the typical EL6910 pre-certified function blocks to form complex, safe drive functions such as SLS, SLP, etc. Depending on the application, the safety-oriented information can be pre-processed directly in the drive so that the central TwinSAFE logic need only process the information that is aggregated there.

The optional multi-feedback interface supports the digital encoder systems EnDat 2.2 and BiSS C. Two further D-sub 15-pin connectors can be found behind the front cover. Therefore, one or two EnDat or BiSS encoders can be connected to a single-axis module. With a dual-axis module, an encoder interface is assigned to each axis.

These encoder systems can be used as primary or secondary feedback interfaces. Primary feedback means that these encoders are used as commutation encoders. This is the case with third-party motors or if a Beckhoff linear motor is operated with this feedback. Example of secondary feedback: An AM8000 servomotor with OCT drives a spindle axis that is additionally equipped with a linear encoder to increase the accuracy.

| Technical data | AX8118-0000-0000 | AX8118-0100-0000 |

|---|---|---|

| Function | axis module | axis module with TwinSAFE Logic |

| Number of channels | 1 | |

| TwinSAFE safe drive technology | – | STO/SS1 |

| Feedback system | OCT | |

| Rated output current (axis) | 18 A | |

| Current control | 1 µs update time, 16 µs cycle time | |

| Peak output current (axis) | 40 A | |

| DC-Link voltage | max. 875 V DC | |

| DC-Link capacitance | 405 µF | |

| Power loss | 22 W | |

| System bus | EtherCAT | |

| Drive profile | CiA402 according to IEC 61800-7-201 (CoE) | |

| Design form | modular system with 90 mm wide elements | |

| Protection class | IP 20 | |

| Ambient temperature (operation) | 0…+55 °C (see documentation) | |

| Approvals/markings | CE, cULus | |

| Realisation STO | by local TwinSAFE Logic, via FSoE or hard-wired via safe inputs | |

| Safety standard | EN ISO 13849-1:2015 (Cat 4, PL e), EN 61508:2010 (SIL 3) and EN 62061:2005 + A1:2013/A2:2015 (SIL CL3) | |

| Technical data | AX8118-0110-0000 | AX8118-0200-0000 |

|---|---|---|

| Function | axis module with TwinSAFE Logic and multi-feedback interface | axis module with TwinSAFE Logic |

| Number of channels | 1 | |

| TwinSAFE safe drive technology | STO/SS1 | Safe Motion |

| Feedback system | OCT, BiSS C, EnDat 2.2 | OCT |

| Rated output current (axis) | 18 A | |

| Current control | 1 µs update time, 16 µs cycle time | |

| Peak output current (axis) | 40 A | |

| DC-Link voltage | max. 875 V DC | |

| DC-Link capacitance | 405 µF | |

| Power loss | 22 W | |

| System bus | EtherCAT | |

| Drive profile | CiA402 according to IEC 61800-7-201 (CoE) | |

| Design form | modular system with 90 mm wide elements | |

| Protection class | IP 20 | |

| Ambient temperature (operation) | 0…+55 °C (see documentation) | |

| Approvals/markings | CE, cULus | CE, cULus in preparation |

| Realisation STO | by local TwinSAFE Logic, via FSoE or hard-wired via safe inputs | |

| Safe stop functions | Safe Torque Off (STO), Safe Operating Stop (SOS), Safe Stop 1 (SS1), Safe Stop 2 (SS2) | |

| Safe direction functions | Safe Direction positive (SDIp), Safe Direction negative (SDIn) | |

| Safe position functions | Safely Limited Position (SLP), Safe CAM (SCA), Safely Limited Increment (SLI) | |

| Safe acceleration functions | Safe Maximum Acceleration (SMA), Safe Acceleration Range (SAR) | |

| Safe speed functions | Safely Limited Speed (SLS), Safe Speed Range (SSR), Safe Speed Monitor (SSM), Safe Maximum Speed (SMS) | |

| Safe braking functions | Safe Brake Control (SBC) | |

| Safety standard | EN ISO 13849-1:2015 (Cat 4, PL e), EN 61508:2010 (SIL 3) and EN 62061:2005 + A1:2013/A2:2015 (SIL CL3) | |

- AT2E VietNam

- Aucom VietNam

- As-schoeler + Bolte Vietnam

- Aira VietNam

- Autrol Viet Nam

- Ashcroft Vietnam

- AEG Vietnam

- Brook Instrument VietNam

- Bircher VietNam

- Bronkhorst Vietnam

- B & K Vibro VietNam

- Baumuller VietNam

- Beckhoff VietNam

- Burkert Viet Nam

- Brugger Feinmechanik Vietnam

- Badger Meter

- Balluff Vietnam

- BEINAT VIETNAM

- CS Instrument VietNam

- CEIA VietNam

- Comet VietNam

- Cosa+Xentaur

- Dwyer VietNam

- DUNGS VietNam

- Dosatec Vietnam

- EMT-Siemens-VietNam

- Emerson | Rosemount VietNam

- Endress+Hauser VietNam

- ECD Vietnam

- Fox Thermal VietNam

- Fireye VietNam

- Fotoelektrik-Pauly VietNam

- FW MURPHY

- Gastron VietNam

- Grant VietNam

- Intorq VietNam

- Ginice Viet Nam

- Gunther GmbH

- Iba VietNam

- IPF Electronic VietNam

- Keller VietNam

- Krohne VietNam

- Kometer Viet Nam

- Kyowa VietNam

- Keofitt Vietnam

- Kiepe

- Knick VietNam

- Kracht VietNam

- Koganei Vietnam

- Labom VietNam

- HBM VietNam

- Matsushima VietNam

- Medenus Vietnam

- Mark-10 VietNam

- Metone VietNam

- Masibus Vietnam

- Novotechnik Vietnam

- ME-Systeme Vietnam

- Micro-Epsilon Vietnam

- Nireco VietNam

- Ohkura VietNam

- OMC VietNam

- PCI Instrument VietNam

- Pulspower

- Pressure Tech Vietnam

- Qualitest VietNam

- Riels VietNam

- Rotork VietNam

- Reckmann Vietnam

- Redlion VietNam

- Rietschoten Vietnam

- UNIPULSE VIETNAM

- Pavone Sistemi VietNam

- Schenck Process

- Sauter VietNam

- Schubert - Salzer VietNam

- Sitec VietNam

- STI Vibration Viet Nam

- Spohn & Burkhardt Vietnam

- Cmovalves Vietnam

- Tokyo Keiki VietNam

- TDK Lambda VietNam

- Tempsens VietNam

- Tema VietNam

- Takenaka VietNam

- Tantronic VietNam

- Tek-trol VietNam

- Taihei Boeki Vietnam

- Vandergraff VietNam

- VORTEX GENIE II / USA

- Vibro-Meter Viet Nam

- VEGA

- Wise VietNam

- Metone VietNam

- Cemb Vietnam

- Okazaki Việt Nam

- Orbinox Vietnam

- Helukabel Vietnam

- Jinda Vietnam

- Hillmar Vietnam

- DMN-WESTINGHOUSE

- Clyde Pneumatic Conveying Vietnam

- Van vòm

- Romer Fordertechnik Vietnam

- Maxcess Vietnam

- R. M.Young Company Vietnam

- VELJAN Vietnam

- HiFlux Filtration Vietnam

- Bush & Wilton Vietnam

- Elau | Schneider Electric

- Magtrol Vietnam

- Rechner Vietnam

- Tester Sangyo Vietnam

- Sensy Vietnam

- IDM Instruments Vietnam

- Hansford Sensors Vietnam

- Hirose valves Vietnam

- Utilcell Vietnam

- Rathicouplings

- Deublin Vietnam

- Ringspann Vietnam

- Nippon Gear

- JNC Valve Vietnam

- GÜNTHER Heisskanaltechnik GmbH

- ID Insert Deal Vietnam

-

Trực tuyến:47

-

Hôm nay:14903

-

Tuần này:140227

-

Tuần trước:138184

-

Tháng trước:259254

-

Tất cả:16054646

-

Đồng hồ đo lưu lượng hơi nước

Ứng dụng phương pháp đo kiểu Vortex.

-

Đồng hồ đo lưu lượng khí | Thermal mass flow sensor for flow measurement

Đồng hồ đo lưu lượng khí | Thermal mass flow sensor for flow measurement

Ứng dụng theo dõi mức tiêu thụ và phân tích dòng rò rỉ của khí chỉ với một thiết bị đo duy nhất.

-

Hệ thống EPC (Edge Position Control) & CPC (Center Position Control)

-

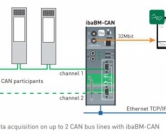

Hệ thống điều khiển, thu thập và phân tích dữ liệu IBA

Hệ thống điều khiển, thu thập & phân tích dữ liệu IBA